An overview from Crisp Malt

An overview from Crisp Malt

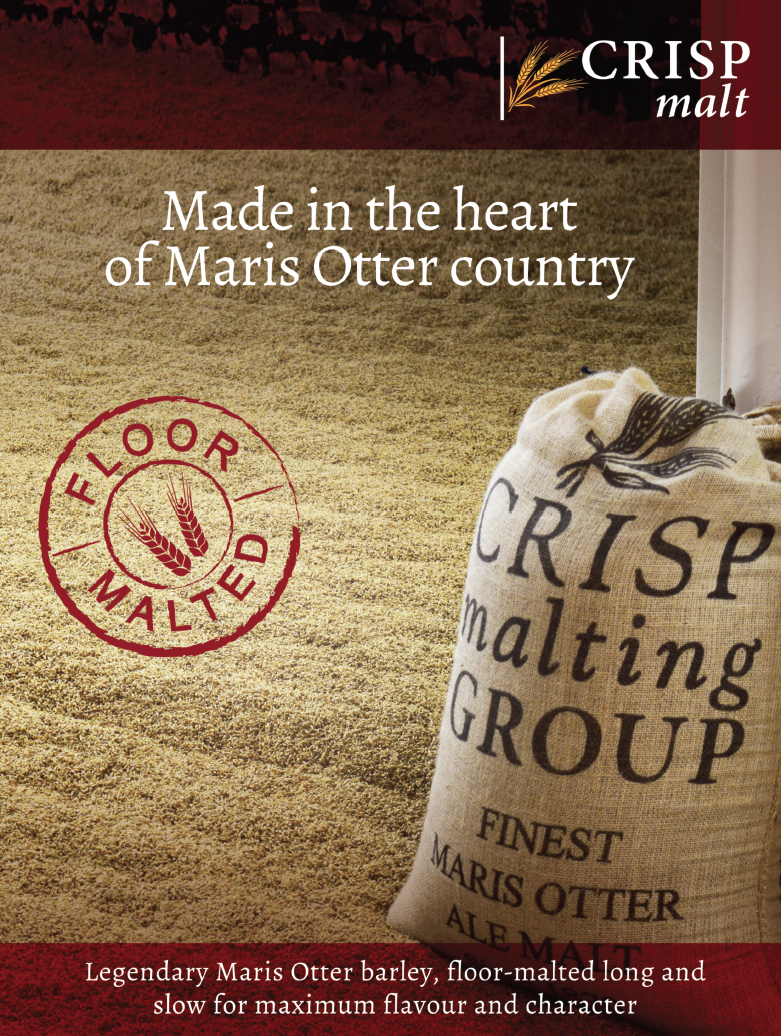

Malting

Malting is nothing new – the process has been around for thousands of years, with historical documents showing malted grains used to make beer in ancient Egypt and China. That said, maltsters are still, millennia later, creating new and exciting malts, which in turn make for unique and interesting beers.

The process begins with steeping. Barley grains are soaked in water to increase the moisture content from around 12% to around 46%, taking two days.

The barley is then moved to a germination floor or vessel. Here the conditions are optimised for growth – with both air temperature and humidity under careful control to maximise enzymic activity. If left too long, the precious extractable sugars will be lost to the roots and shoots of the grain, so timing is imperative.

The grains are then transferred to the kiln, where they are suspended above streams of warm air to drive off the moisture and dry the malted barley until it is stable. The drying process determines the malt’s potential to produce sugars in the brewhouse. It also controls the colour and flavour of the finished malt.

Pale Malt

The majority of the malt in beers is pale malt. This has a sweet, slightly biscuity smell – think of Horlicks and you’re there! …

To read the complete article, turn to page 34 of our Summer 2018 issue. Read our latest issue, here.